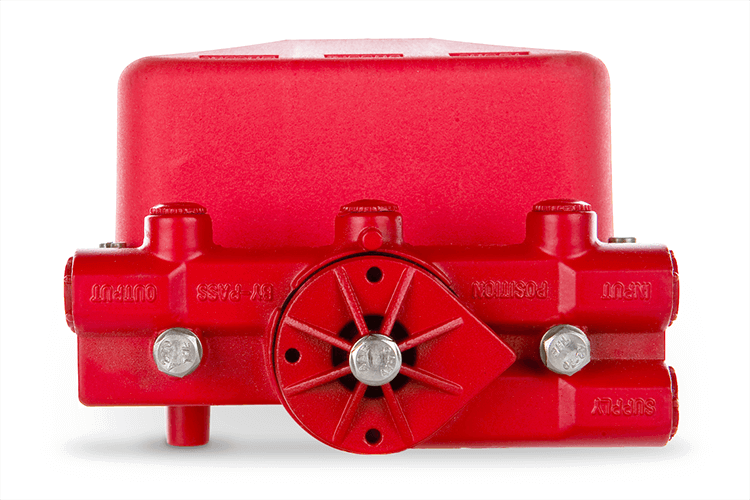

Valve Positioners

Pneumatic and Electro-Pneumatic

Both versions of our valve positioners come with a robust, rugged case. Depending on the specification, this is made from either aluminium or stainless steel. It is then mounted on a heavy-duty plate, enabling it to operate reliably and effectively, even in the presence of significant vibration.

The P3300 can be made of either aluminium or stainless steel. It operates at temperatures as low as -20°C as standard, but can be adapted to operate as low as -40°C where required by the specification. It operates with very high levels of accuracy and repeatability, with very low levels of hysteresis.

The P3300i is a milliampere signal version, which includes all of the main features of the P3300, but can operate from a standard 4-20mA signal.

performance specifications

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.