SUBSEA SOLUTIONS

First-class engineering backed by specialist knowledge

trim options

High Friction (HF) Cartridge Trim Design

A solid tungsten carbide trim with a built-in ‘brick stopper’. Used on most standard applications.

High Friction Triple Stage (HFT) Trim Design

A variable stage trim to accommodate high pressure drops at low flow openings. Used on most high-pressure water injection applications.

Micro/Multi-Spline Trim Design

Can accommodate pressure drops of up to 500 bar. Used on most MEG/methanol and chemical injection applications.

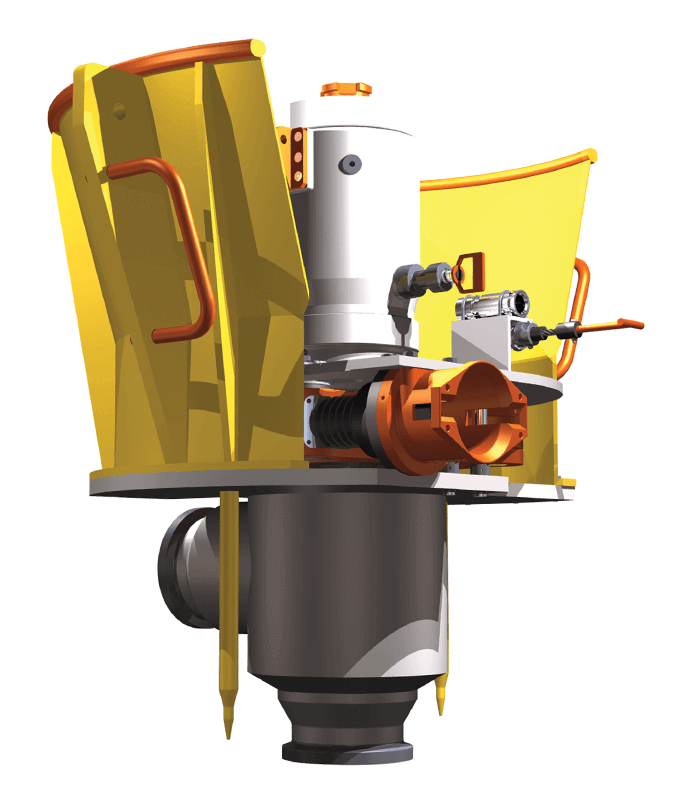

retrieval options

Depending on the specification, some choke valve inserts may require retrieval or removal for maintenance. The Series 75 range allows for the following options:

- Non-retrieval

- Diver retrieval

- Remote retrieval using ROV and our Intervention Work Over System

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.