Pipeline surge relief control

OVERCOMING PIPELINE SURGES

If a valve or pump suddenly fails or trips out, the flow at that point comes to a stop. Meanwhile, either side of the fault, fluid will at first flow as normal due to its mass momentum. Upstream, the fluid will start to compress, causing a pressure surge.

However, downstream the fluid will eventually see a rarefaction in pressure, encouraging a reverse flow. On a pipeline with a normal operating pressure of 17.5 bar a surge can generate a transient pressure of 96 bar if uncontrolled, emphasising the importance of anti-surge conditions.

One customer was experiencing severe vibration due to cavitation with a competitor’s control valve. We were asked to supply a trial control valve that would:

- Eliminate the cavitation.

- Provide stable control while subjected to extremely high velocities.

- Fit into the existing space on the pumping station.

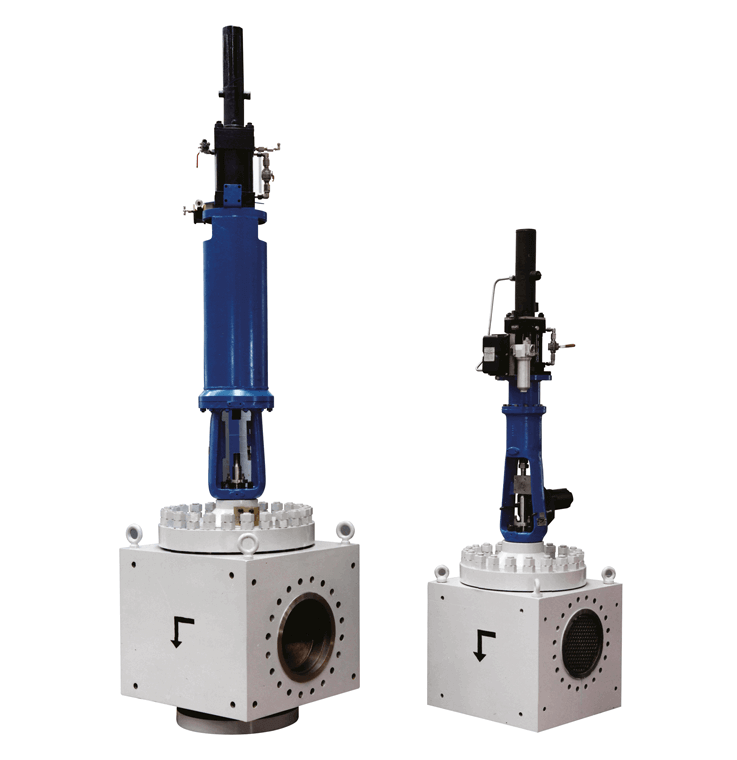

We specified seven stages of pressure drop to ensure that the pressure of the medium did not fall below the vapour pressure. This prevented cavitation, achieving the required low noise level and eliminating the vibration that had previously been experienced. Great care was also taken to control the flow velocity through the control valve. Although it was specified as a 16″ angle design, the trim components and size were the same as used on a 24″ valve.

Prior to shipment to Alaska, the control valve was fully tested for confirmation of both the CV and flow characteristic. After successful extensive customer trials we received an initial order for 36 of these anti-surge pipeline control valves, each one specifically designed around the flow conditions of each individual pump. We subsequently received and delivered an order for ten more units. The valves continue to function satisfactorily with minimal service requirement.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.