TECHNICALLY ADVANCED SURFACE CHOKE VALVES

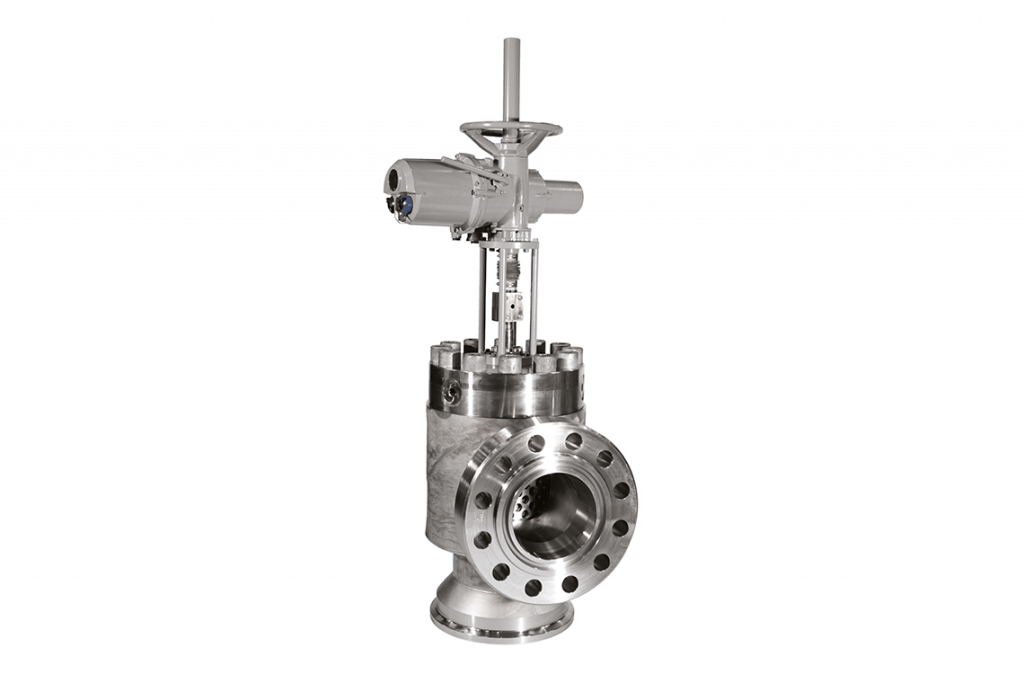

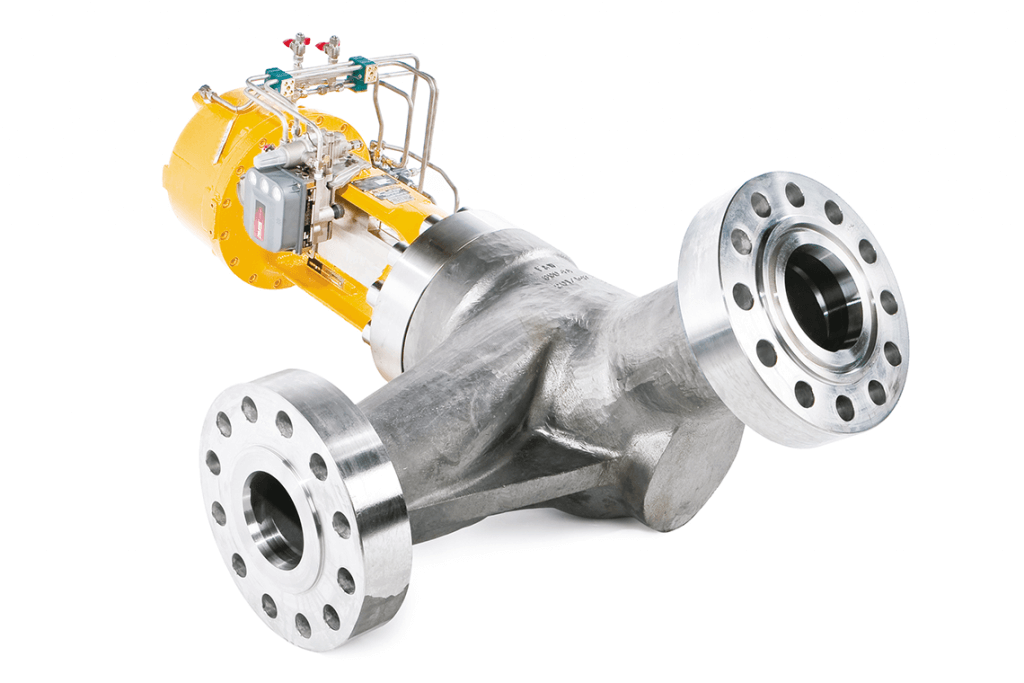

SERIES 73

TECHNICAL SPECIFICATION

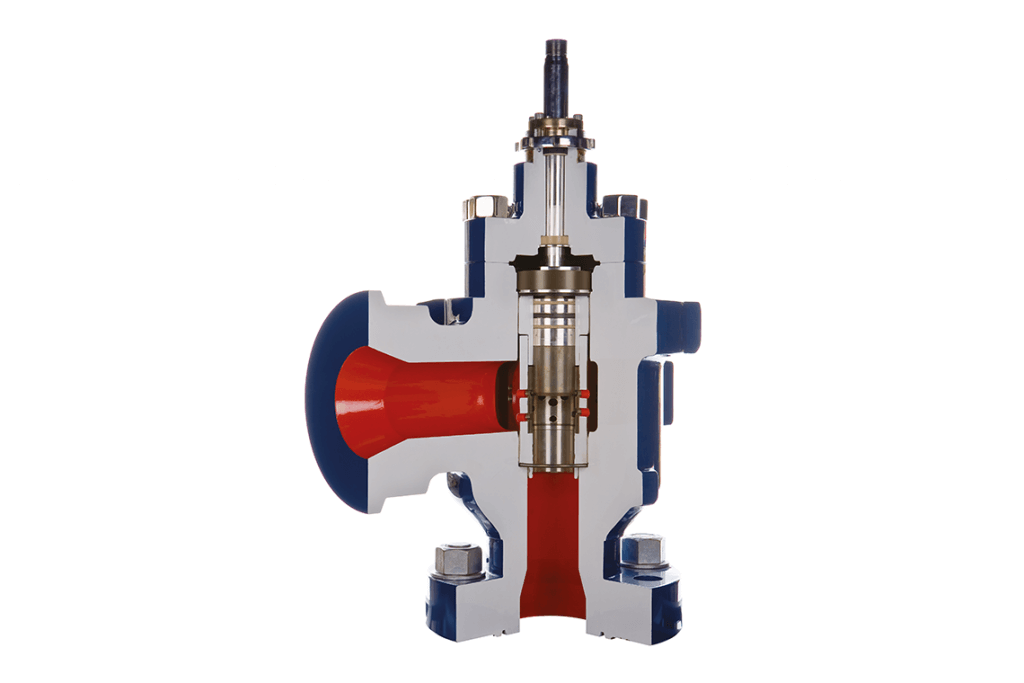

trim design

All Series 73 Choke Valves use a low-pressure recovery, High Friction trim design. This protects the vital pressure-containing boundaries of the valve against damage from erosion and cavitation. It does so by dissipating and controlling velocity, pressure, energy and turbulence within the confines of the trim. Dependent on the needs of your project, the Series 73 range can work with single or multi-stage trims.

Multi-stage trims can protect the valves further against the effects of cavitation and high velocity erosion. Holes in the trims are aligned in such a way as to force individual jets to change direction repeatedly as they pass through the chambers between sleeves. This results in a controlled, steady reduction in pressure and velocity control preventing the onset of cavitation.

VECTOR™ – VELOCITY CONTROL CHOKE TRIM TECHNOLOGY

On the most onerous applications where there are extreme pressure drops and very high velocities, the VECTOR™ solid Tungsten Carbide Velocity Control trim would be utilised.

The main features of this trim are:

- Up to 10 stages of discrete velocity control.

- Large flow passages to allow solid contaminates to pass through the trim.

- Premium-grade solid tungsten carbide critical control / throttling elements.

- Various trim sizes can be used in different choke valve body sizes, to suit a wide range of process control parameters.

- Resilient balance seals complete with scraper rings.

- Metallic ‘brick stopper’ to prevent solid particles impacting directly on to the tungsten carbide.

'HF' High friction cartridge trim

This option is used on most applications to protect against erosion and cavitation.

The main features of this trim are:

- Divides the main flow into many small streams, increasing turbulence and noise peak frequency and maximising the pipe wall transmission loss.

- High energy levels, pressure and velocity are dissipated within the confines of trim – avoiding erosion damage.

- Design of final stage ensures low-velocity non-interacting jets, avoiding unnecessary noise generation in the choke outlet.

- Various trim sizes can be used on different choke valve body sizes, to suit a wide range of process control parameters.

- The inner tungsten carbide control elements are protected from impact damage by the outer cartridge sleeve.

High Friction-LCV anti-erosion trim

Some applications come with the additional risk of sand contamination. The patented HF-LCV trim has been designed to meet the challenges of such demanding and erosive conditions. It has been independently tested and proved highly effective.

The main features of this trim are:

- Premium-grade solid tungsten carbide critical control / throttling elements.

- Solid tungsten carbide sacrificial plug nose.

- Shrouded plug seat, protected from the highly erosive flow path.

- Hole development dead band – the seating area is removed from the main flow area.

- Stem scrapers prevent migration of sand into the stem seal area.

- Resilient plug seals with scraper rings.

- Metallic ‘brick stopper’ prevents solid particles impacting directly onto the tungsten carbide.

- Optional tungsten carbide wear sleeve.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.