SUBSEA SERVICES & SUPPORT

Providing efficiency and peace-of-mind

Our Subsea Professional Services

OUR SUPORT SERVICES

- The valve is stripped, cleaned and inspected in accordance with ISO 10423 (API 6A) appendix J.

- A full technical report is issued to the client for consideration including a list of re-usable parts and recommendations for refurbishment. This may include product enhancements.

- Once the recommendations are approved, the valve is refurbished and staged ready for assembly and factory acceptance test. Where required this can be witnessed by a client or third party to ensure that all standards are adhered to.

qualification and testing

Our support team can also provide the following services to assess the working capability of your valves and equipment:

- Choke PR2 test in accordance with ISO 10423:2002

- (ANSI/API 6A) Annex F

- Hyperbaric test in accordance with API 17D to 2300m water depth (designed for 3000m)

- Endurance million step test at 3,000 and 5,000 psi LP system pressures with variable choke load conditions

- Hydraulic power unit with PLC control for factory acceptance

- testing (FAT)

- Self monitoring million step test hardware and software with

- 24 hour testing capability

- Dedicated gas test facility rated to 16.5k psi

- Liquid CV flow test facility rated to 600m³/h

- Environmental chamber for performance testing at choke design extremities

- Finite Element Analysis

- 3D Modelling & Computational Fluid Dynamics Analysis

- Trim impact testing

- Fugitive Emissions Testing

At project-specific level, we can also carry out independent erosion testing, slurry testing and SIT interface testing.

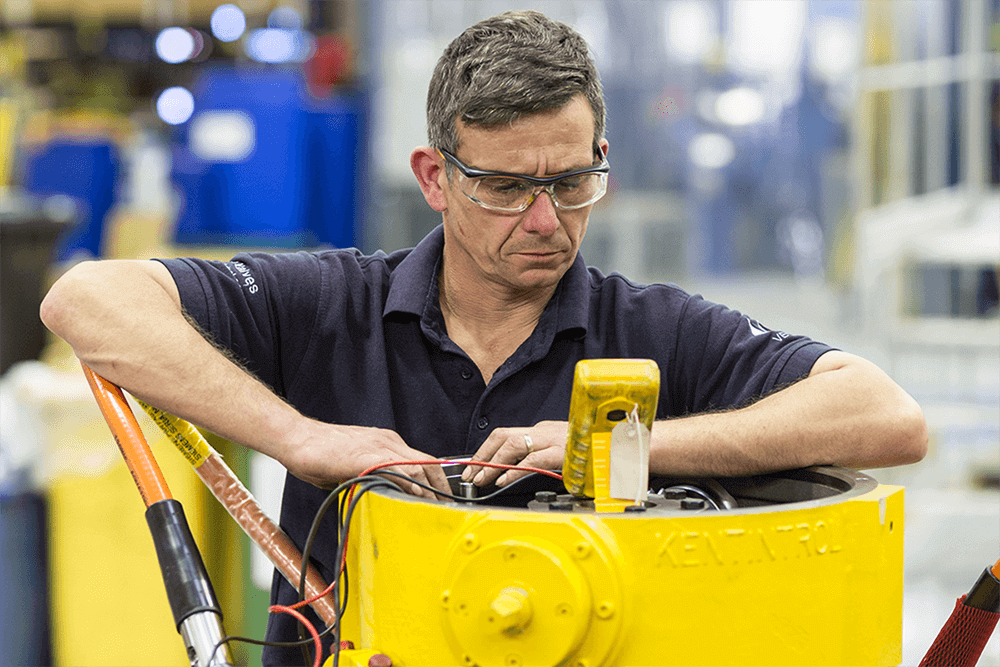

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.