WATCH OUR VIDEOS ON VALVE DIAGNOSTICS

VALVE DIAGNOSTICS

PREDICTIVE VALVE MAINTENANCE

How advanced data analytics is leading the future of valve maintenance

There’s been a shift in the way customers use diagnostics in the oil and gas industry. Customers are now investing heavily in data analytics that allow them to monitor valve performance online at any time. For the issues that can’t be detected by built-in systems, Kent Introl can step in and take advanced data analytics to the next level.

The benefits of running valve diagnostics on your assets

Valve diagnostics can be a contentious subject. With our data acquisition equipment, we are able to regularly and precisely measure the performance of a valve that may be degrading over time. By gauging results at intervals and using the same parameters, we can analyse trends and make recommendations based on this, including beneficial systems and future maintenance.

How our clients are currently benefiting from valve diagnostics

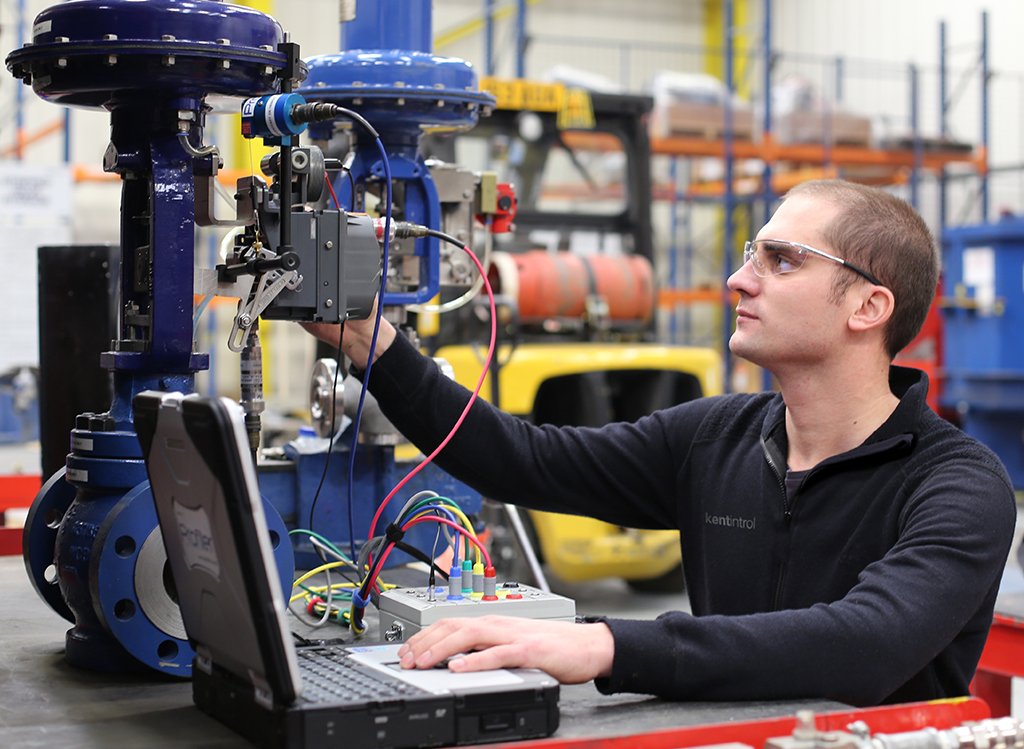

Kent Introl work on-site with clients to analyse diagnostics and ascertain the valves that need attention. In some cases, valves can remain in line and only require minor work. This instantly cuts the costs involved in valve servicing and maintenance. With valve diagnostics technology, we can offer clients expert insight and recommendations as well as making significant savings.

How valve diagnostics integrates into Kent Introl’s specialist valve expertise

Our valve diagnostics equipment completes our vast suite of services. When it comes to data analytics, we are able to apply our expertise to a valve that we’re already very familiar with. We retain the details of all the equipment that we design, build and supply. This sets us apart from competitors who may not fully understand a design that we’ve implemented.

SPEAK WITH A VALVE DIAGNOSTIC EXPERT TODAY

Industry research over the years has shown that although a high proportion of valves need some sort of rectification, they can often be fixed without removing them from service.

- 75% of installed valves require rectification

- Just 11% required removal from the line

- 46% had calibration problems

- 13% did not open fully

- 20% had problems with packing leakage or suffered performance problems due to high packing friction

- 14% of I/P units were defective or not calibrated correctly

- 23% of valves had insufficient seat load causing poor shut-off.

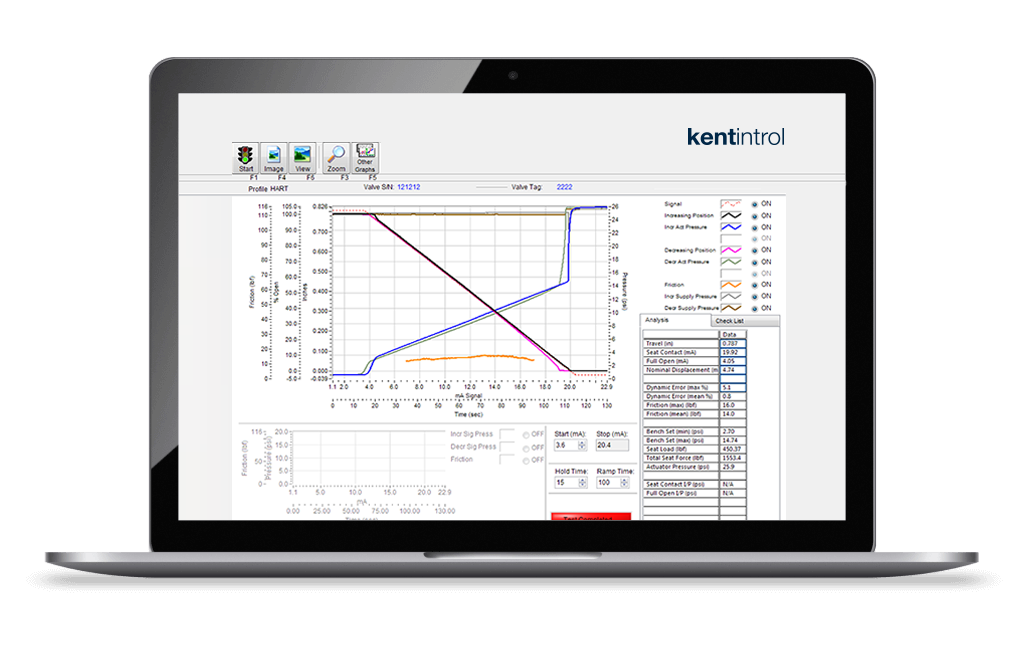

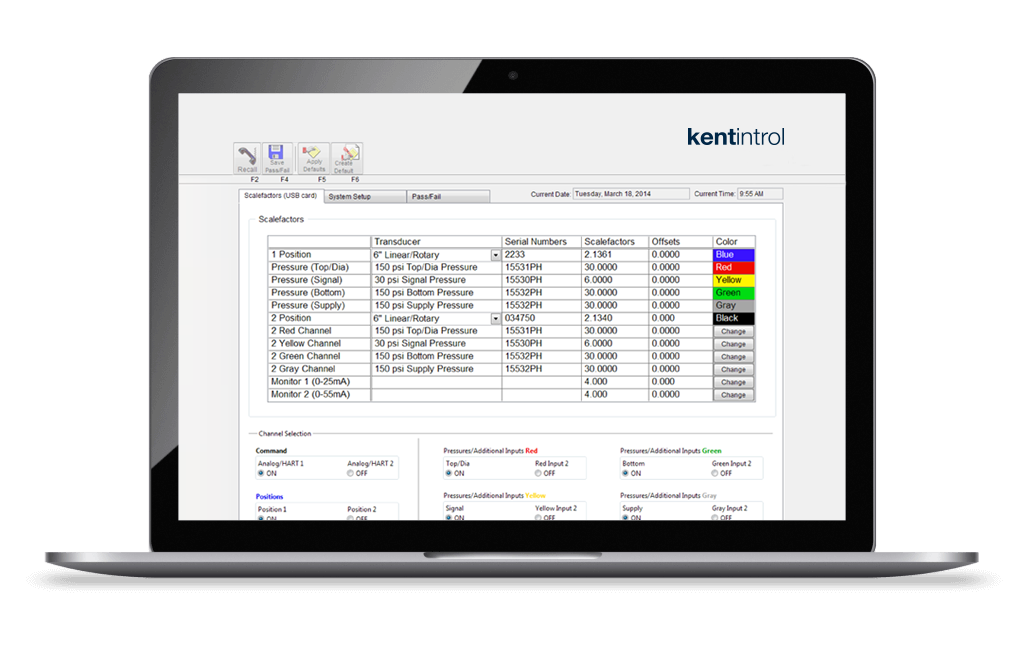

TYPICAL ANALYSIS REPORTS

Our field engineers will use our proprietary valve diagnostics equipment to document and inspect key performance data from a process control valve. This can be done ‘on bench’, or while the valve remains in service. They will explain and interpret this data for you, and give recommendations as to the maintenance strategy for the equipment.

By tracking the data over a period of time, they can proactively monitor for degradation in performance of the valves and equipment. It may also highlight more minor maintenance work that can be carried out on-site without needing to take the equipment out of service.

Our valve diagnostics equipment can be used to detect and document a variety of issues including:

- Air starvation and actuator leakage

- Positioner calibration and linkage issues

- High or low friction

- Hysteresis, deadband and linearity errors

- Stiction

- Seat loading and condition

- Travel faults

- Actuator bench set and spring load.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.