VALVE TESTING

professional valve testing

We carry out gas testing of valves to ISO15848 standards, to ensure that the valve‘s body bonnet joints or gland packing are not leaking. We have one of just a few high-pressure gas testing pits in the UK. It allows gas testing with helium or nitrogen, to 1.1 times a valve’s maximum specified working pressure (to 1,500 bar, or 22,500 psi).

The pit contains 6,000 litres of water and is sunk to a depth of 2.5 metres, allowing even the largest of valves to be tested, in the safest possible environment. The built-in water treatment system not only ensures the water is kept clean and at a uniform pH level, but also uses corrosion inhibitors and biocides to protect the valves, ensuring they do not rust during testing.

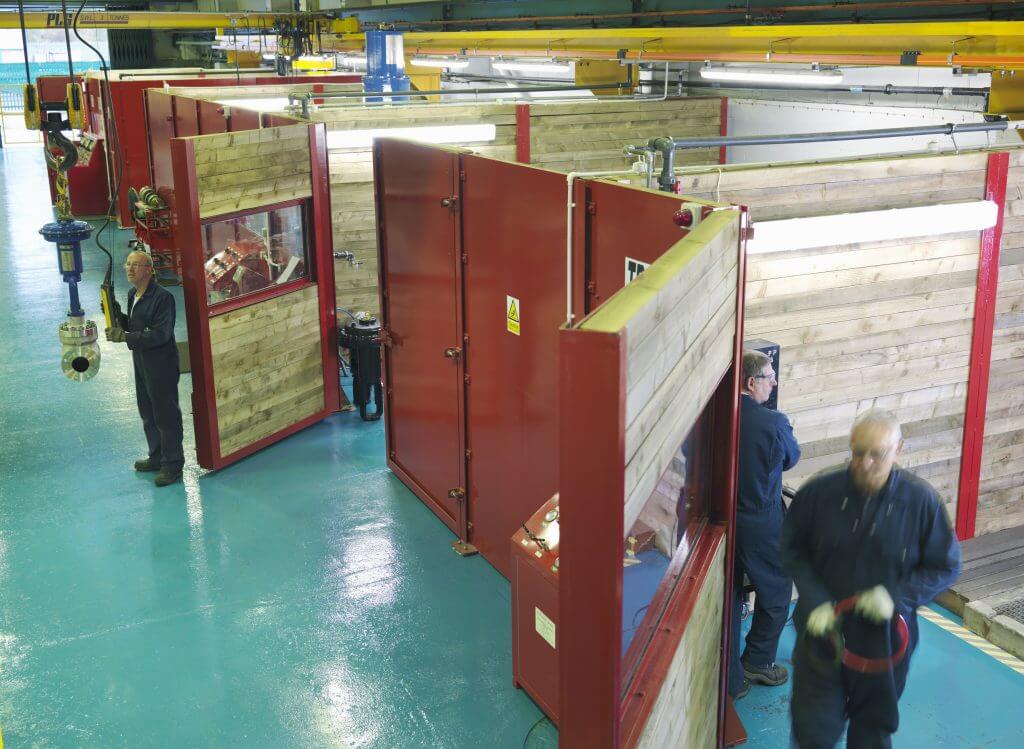

To ensure operator safety, the facility is housed behind 4” thick timber doors lined with 10mm of steel. It is also protected by reinforced concrete walls and an access control system.

A PLC (programmable logic control) system allows us to instantly assess the valve’s performance, as well as sharing and storing this information digitally.

Our bespoke tensile load testing rig helps ensure that any special lifting interfaces are capable of twice the gross weight or greater. The rig is 4.3m high and weighs around 8 tonnes.

Meeting the rigorous standards of Eurocodes 1 and 3 the rig stands at 4.3m high and weighs approximately 8 tonnes. It can test objects of any type and dimension up to 2.5m x 2m x 2.5m, accommodating tensile and compressive strength tests up to 10 tonnes. Individual valve assemblies under test are subjected to tensile or compressive forces of twice the gross weight specified on the assembly.

PR2 Testing examines a valve’s performance under the combined effects of temperature and pressure. We work to API6A/ISO-10423 and ISO-13628-4 standards. PR2 Testing exposes valves to extremes of high and low temperature, whilst cycling between different levels of pressure. This ensures the integrity of the valves and its components.

Valve capacity or ‘CV’ can be tested using a simple water flow circuit. This incorporates an accurate measurement of the flow-rate and the upstream and downstream pressures. We can accommodate any size of valve in these tests.

Our fugitive emission testing works to ISO15848-1 standards, and ensures that all equipment is working in an efficient, environmentally-friendly way. It identifies any leakages in critical components by using helium or nitrogen.

Fire testing of valves is generally a requirement for isolation or primary shut of valves. For one particular North Sea project the client requested to qualify a range of Surface Choke products in accordance with API 6FA.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.