Velocity control trims

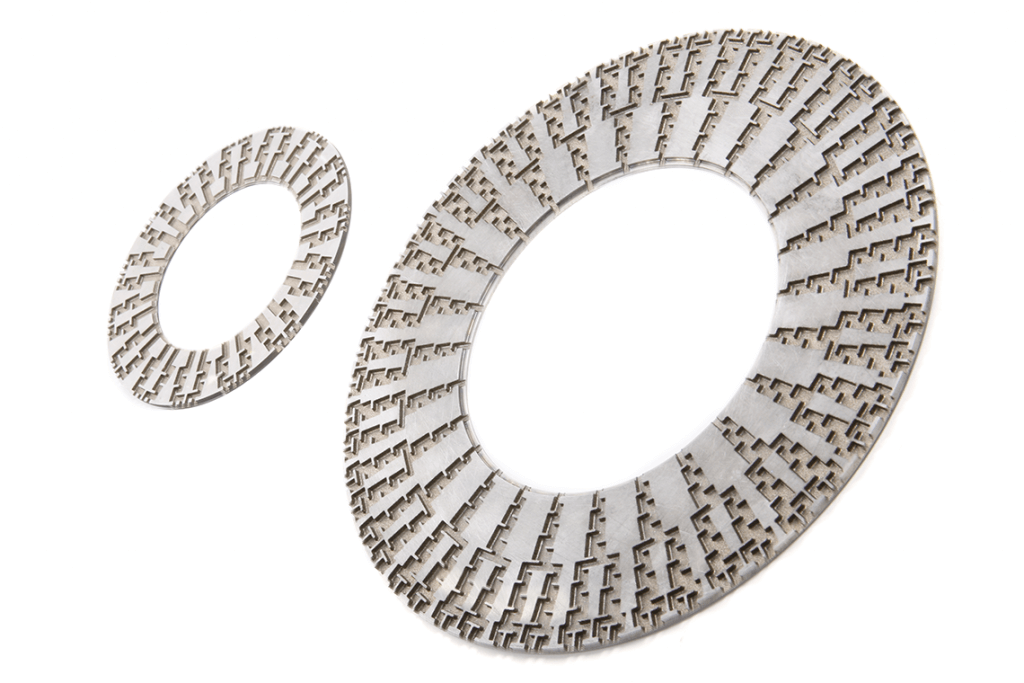

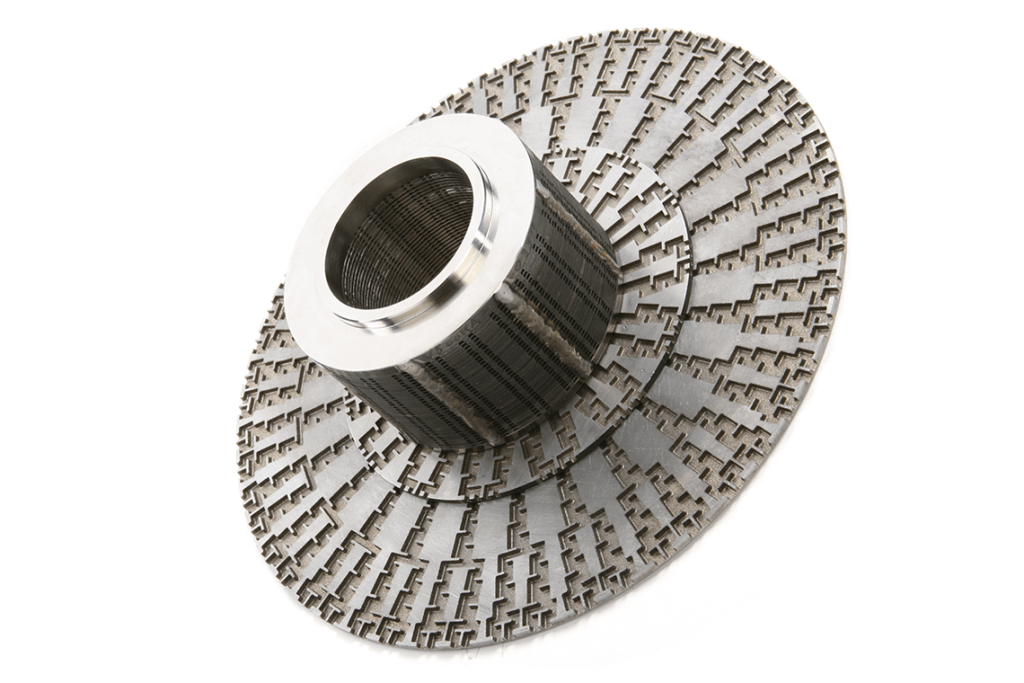

VeCTor™ Velocity Control Trims

How does it work?

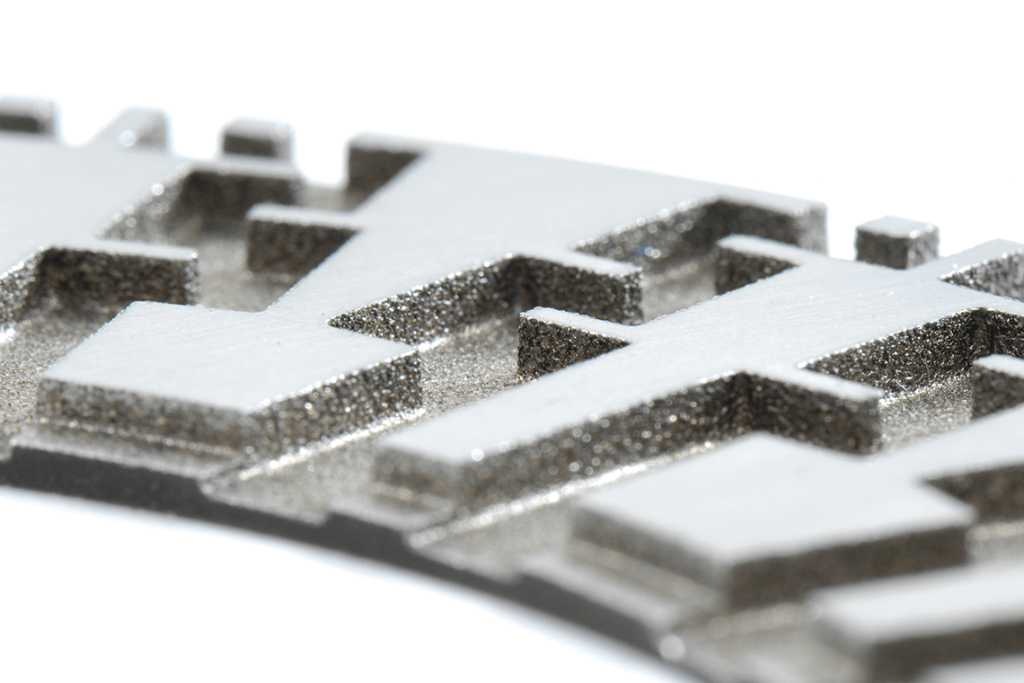

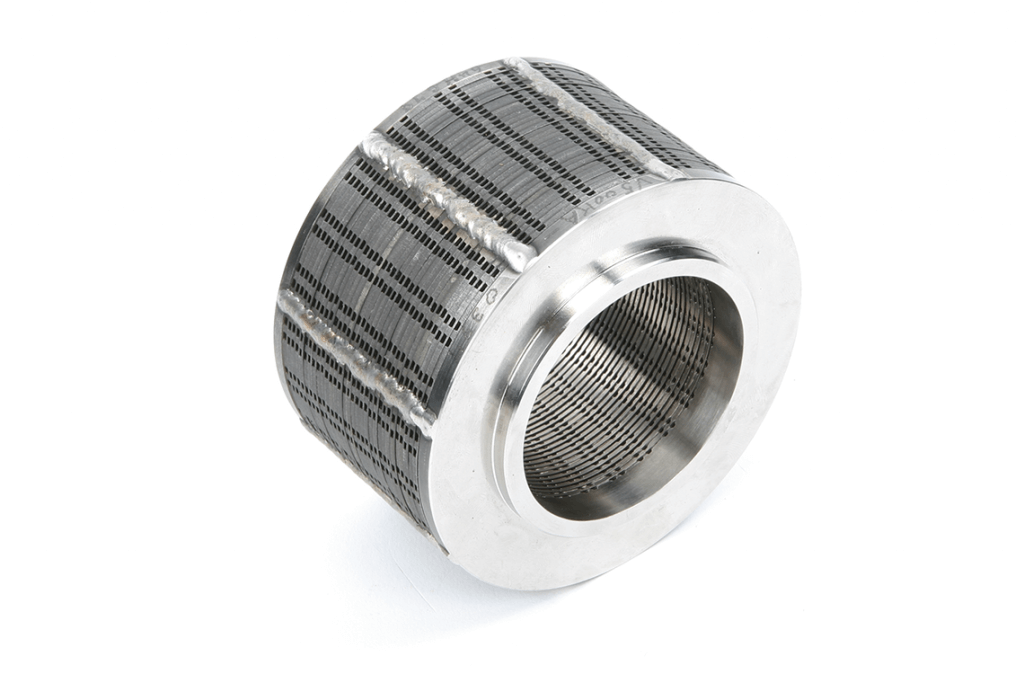

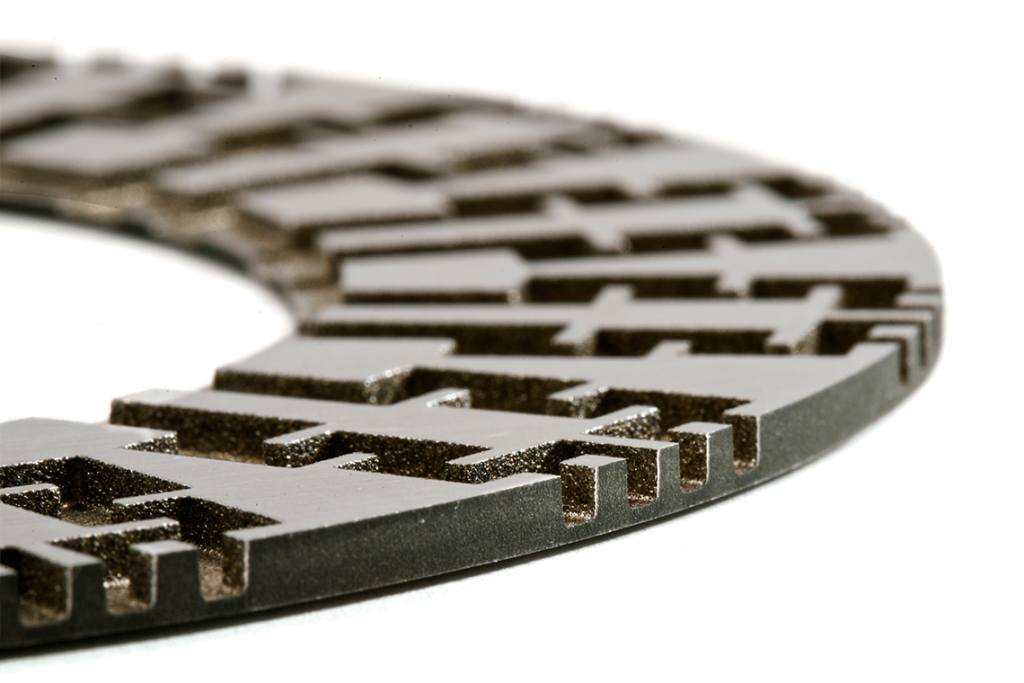

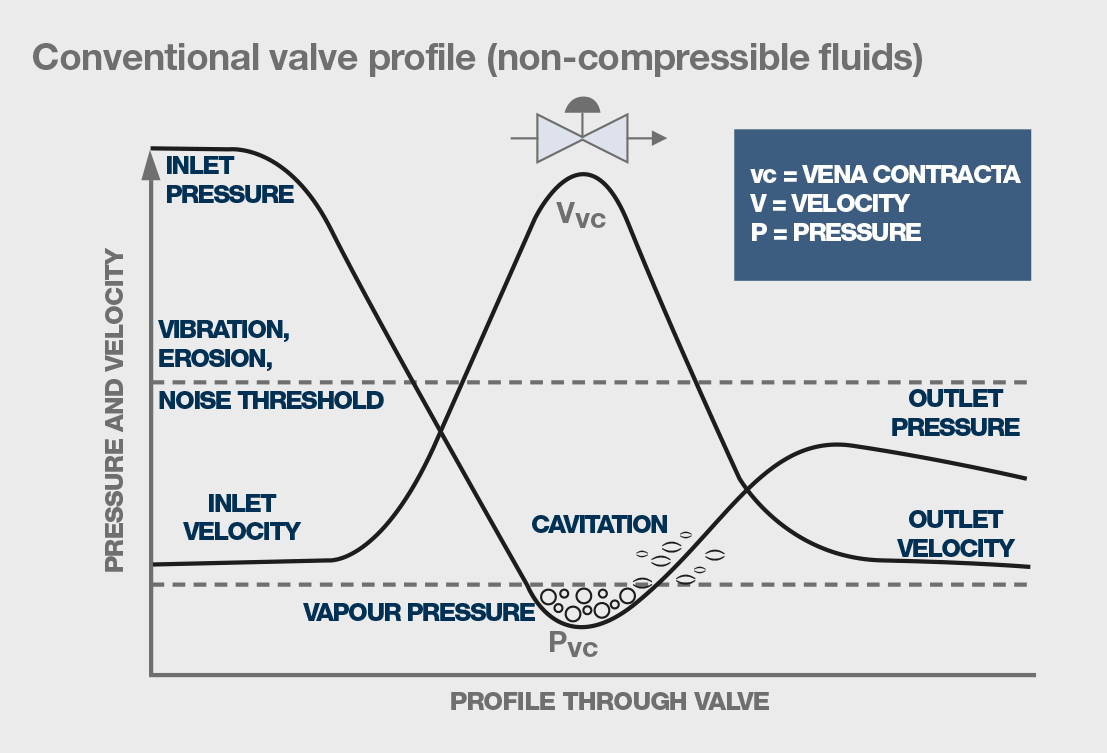

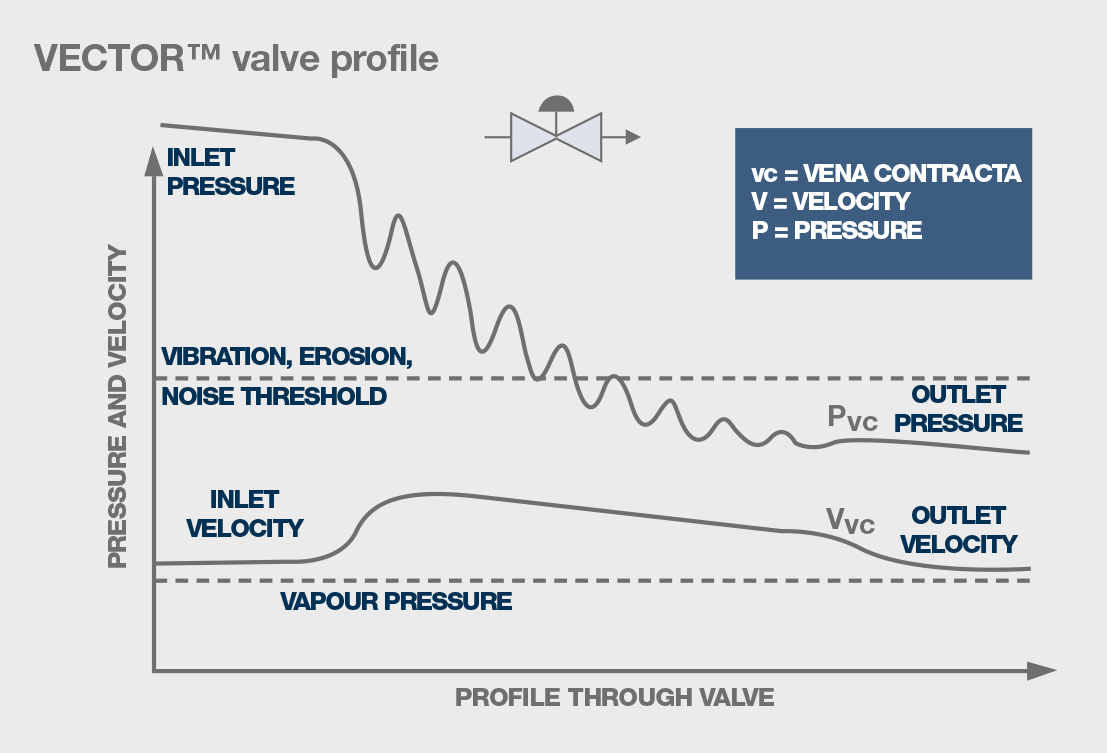

The VeCTor™ labyrinth trim limits harmful flow velocities by separating the flow into smaller individual channels. This stages the full pressure drop across multiple turns in the fluid path. This gives lower pressure drops within the trim, resulting in much lower velocities that are well within the erosion threshold for most trim materials.

Symptoms of poor velocity control can include:

- Unplanned shutdown.

- Lost production.

- High maintenance costs.

- Reduced efficiency.

- Manual control required.

- Noise.

- Trim and body wear.

- Pipe and valve vibration.

- Leakage.

- Pipe erosion.

Symptoms of cavitation:

- High levels of vibration.

- Sporadic, pinging noise, that sounds like rocks passing through the valve.

- Valve components showing ‘pitting’ damage.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.