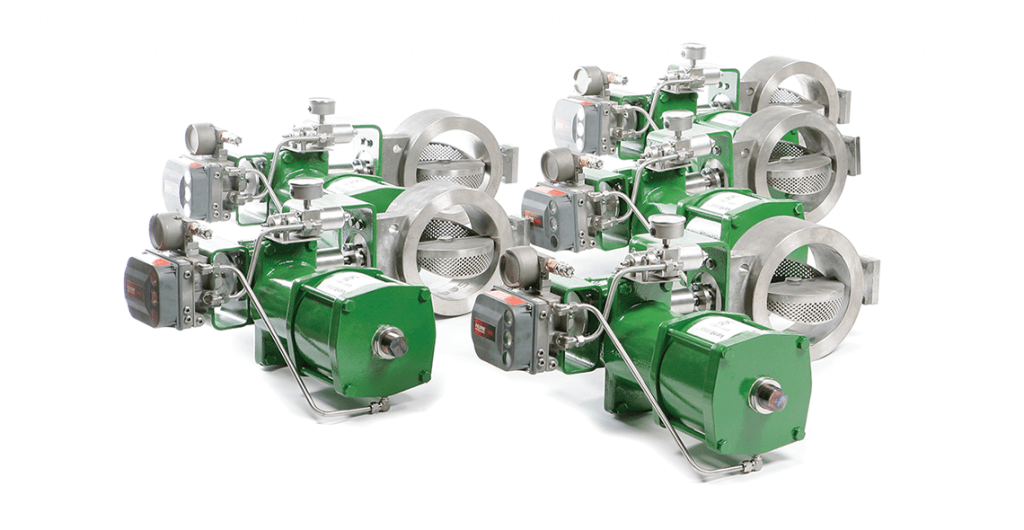

BUTTERFLY CONTROL VALVES

Versatile design for a wide range of applications

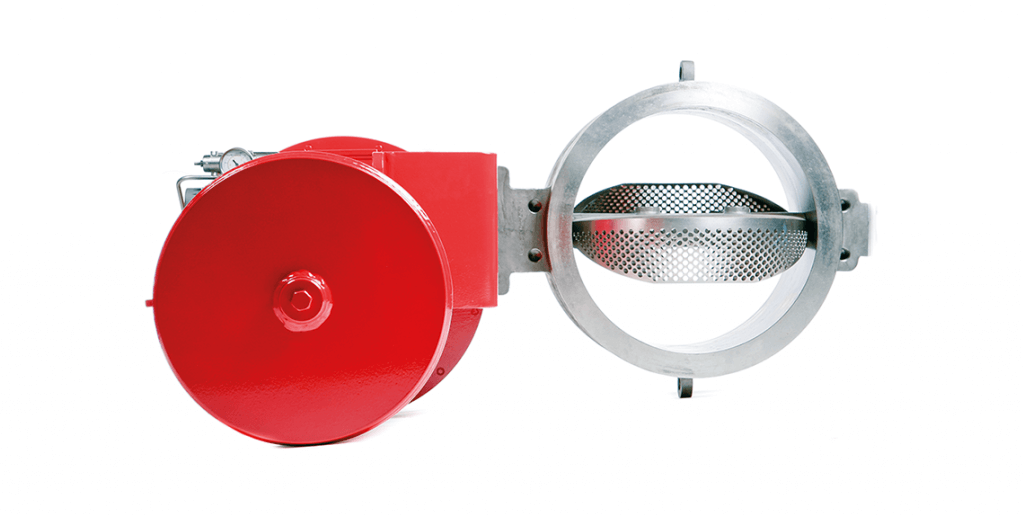

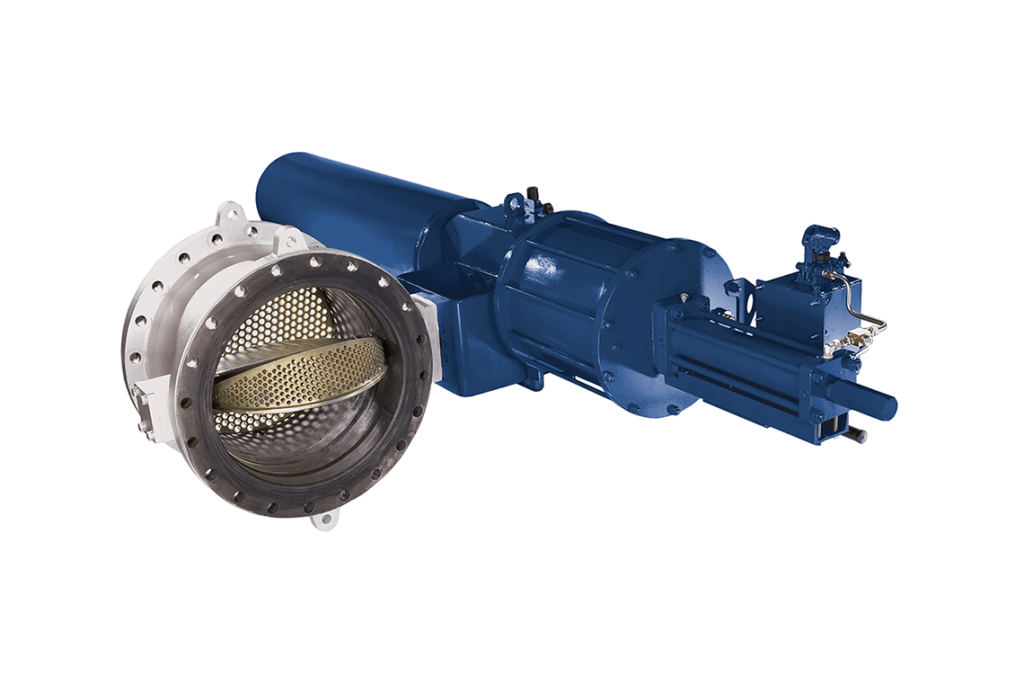

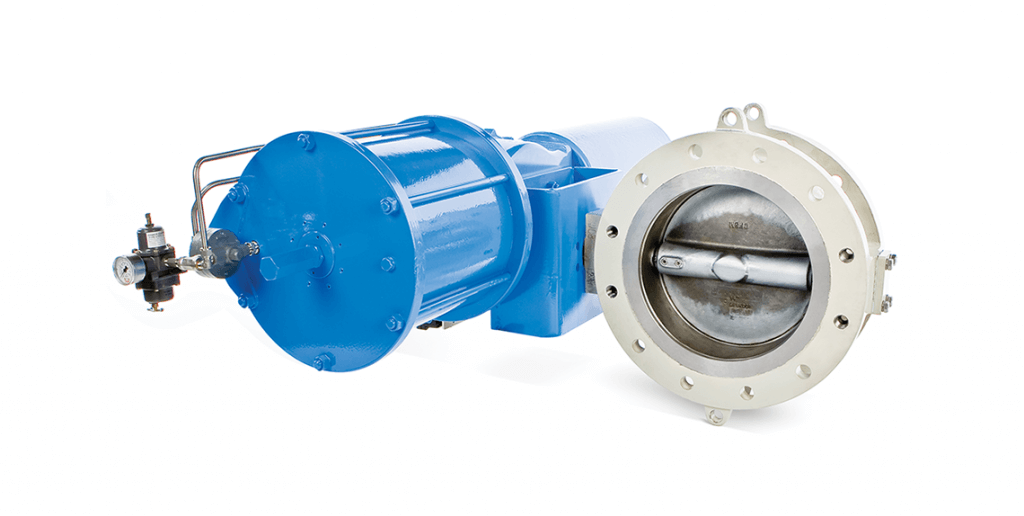

rotrol valve

A major disadvantage of conventional butterfly and ball valves when used in throttling applications is the effect of cavitation which can commence at quite low values of differential pressure. This, coupled with high noise emissions may result in rapid mechanical wear and early failure of the valve components.

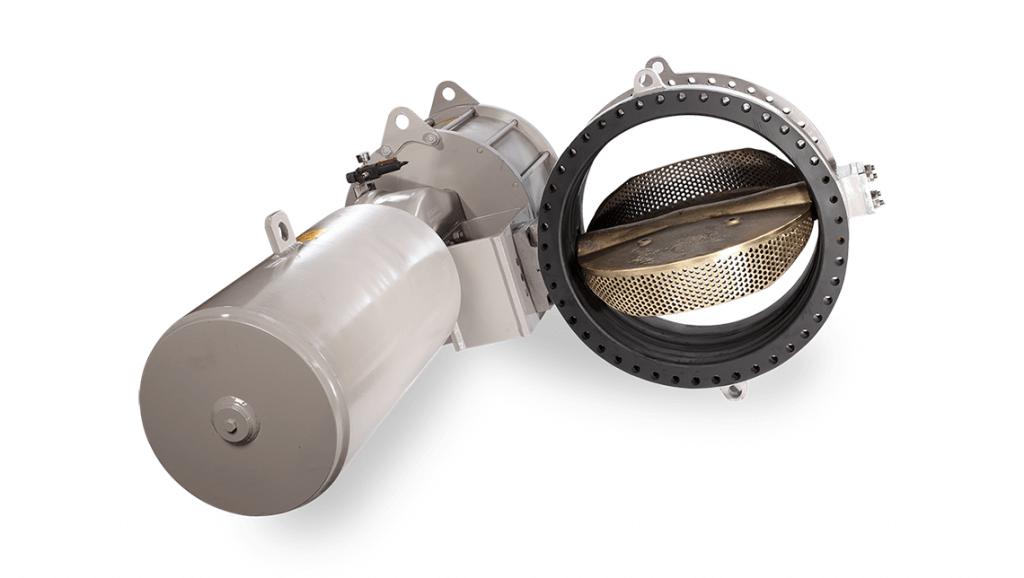

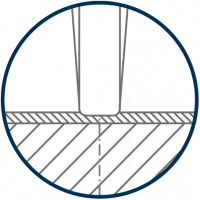

To offset these effects, we have developed a rotary control valve with improved performance capability. The innovative design incorporates a profiled vane which has cowls on its leading and trailing edges. These cowls are drilled with a large number of holes as can be seen above. The function of these cowls, which normally cover about one third of the 90º travel, is to split up the flow stream and dissipate the energy created by the pressure drop across the valve. This allows the valve to handle higher pressure drop and higher velocities without the onset of cavitation and noise. This specialised valve performs exceptionally well in severe service applications with its variable resistance trim, where the pressure drop tends to be high in the controlling position but where high capacity through puts at low pressure drops are also required.

Series 63 butterfly valve

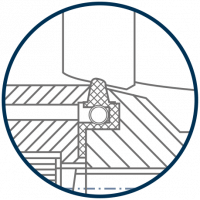

Valve type: Introseal soft-seat

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: VI

Temperature (ºC): -196 to +235

Series 64 butterfly valve

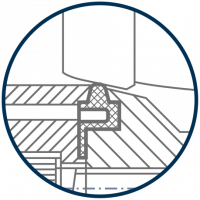

Valve type: Introseal metal-seat

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: IV

Temperature (ºC): -196 to +600

Series 65 butterfly valve

Valve type: Introseal Firesafe

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: VI

Temperature (ºC): -196 to +235

Series 66 butterfly valve

Valve type: Introseal (no seat)

Sizes: 6” to 48” (150mm to 1200mm)

ANSI Rating: 150 to 2500

Disc configuration: Standard and Rotrol

Body style: Wafer, flanged lugged

Leakage class: II

Temperature (ºC): -196 to +800

OTHER FEATURES

High flow coefficient

- Anti-cavitation, low-noise vane design.

- Lighter weight and more compact than a globe valve.

- Superior seat and stem seal integrity.

- Profiled vane with cowls on leading and trailing edges to dissipate energy created by pressure drop across the valve.

- Baffle plates fitted for noise attenuation.

- High rangeability – excellent control between 5° and 90° of opening.

- Operating torque requirements are around half the conventional butterfly valve requirements, requiring smaller more compact actuators.

- Complete range of body materials.

Our many accreditations and processes give you peace of mind when buying from Kent Introl. These include OHSAS 18001, ISO9001, ISO/TS29001, ISO14001, PED Certificate API 6A, API 17D Monogram and more. Visit our Accreditations page to find out more.

We continually invest in all areas of the design, testing and manufacturing process to bring you the right products at the right time, at a competitive price. This gives us ever-greater control over the timing and quality of all aspects of the manufacturing process. Visit our Research and Development page to find out more.

We can assist you right through the lifecycle of your valves and other equipment. Whether you need hands-on servicing and support, or technical training to help your own team, we have the expertise to help you maximise the performance of your valves. Visit our Services page to find out more.