40 years of successful topside applications with the Velocity Control principle.

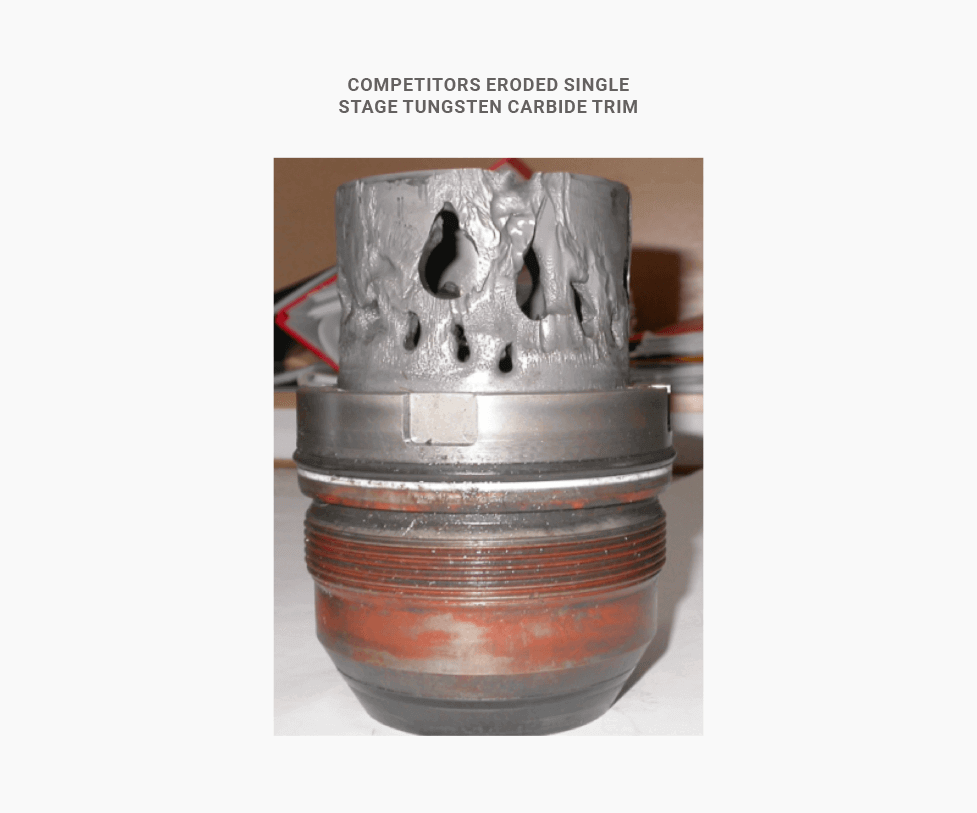

It is common for control & choke valve manufacturers to select a single stage pressure reduction trim solution to handle severe flow applications. In most choke applications these solutions will incorporate a solid tungsten carbide trim to avoid erosion. If the application is relatively benign the single stage solution should perform satisfactorily in most instances. However erosion can occur very quickly on high-velocity applications if the correct Velocity Control methodology is not followed.

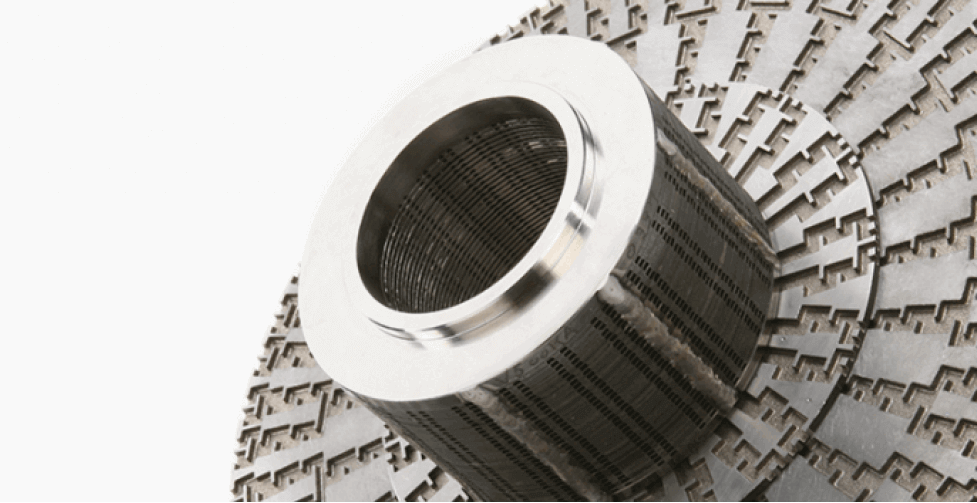

Velocity Control Trim Technology has been used successfully by Kent Introl for over 40 years on topside applications. Extending the capabilities of trim design into severe service, our trims are designed to counter the damage that can be caused at high velocities as well as overcoming the problems of flashing and noise. They can be used in any high temperature or high-pressure drop service.

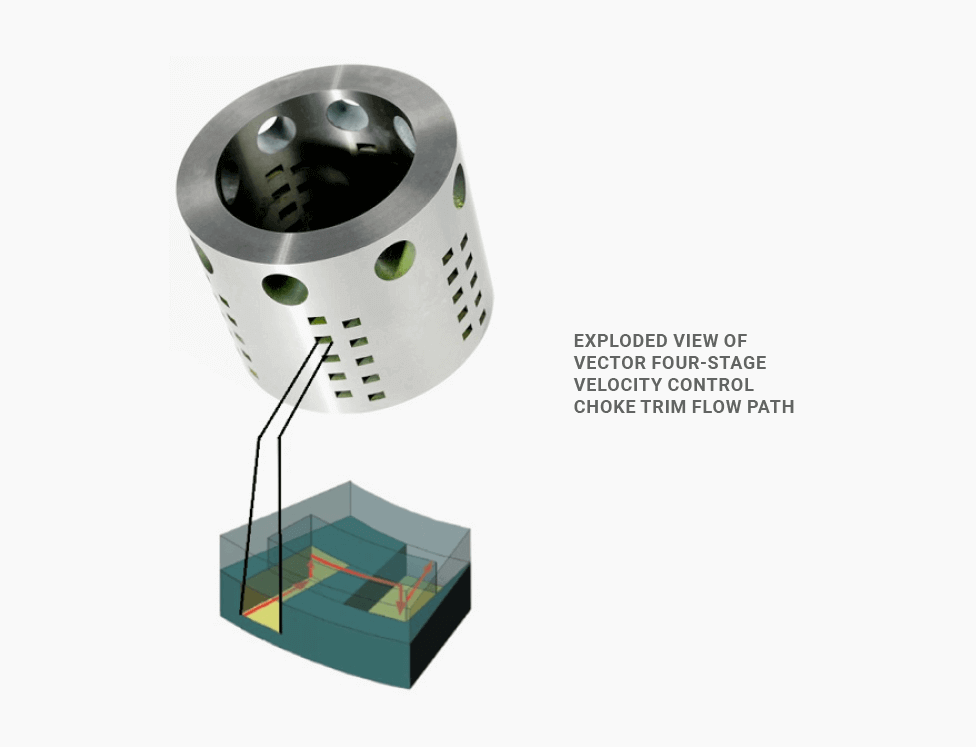

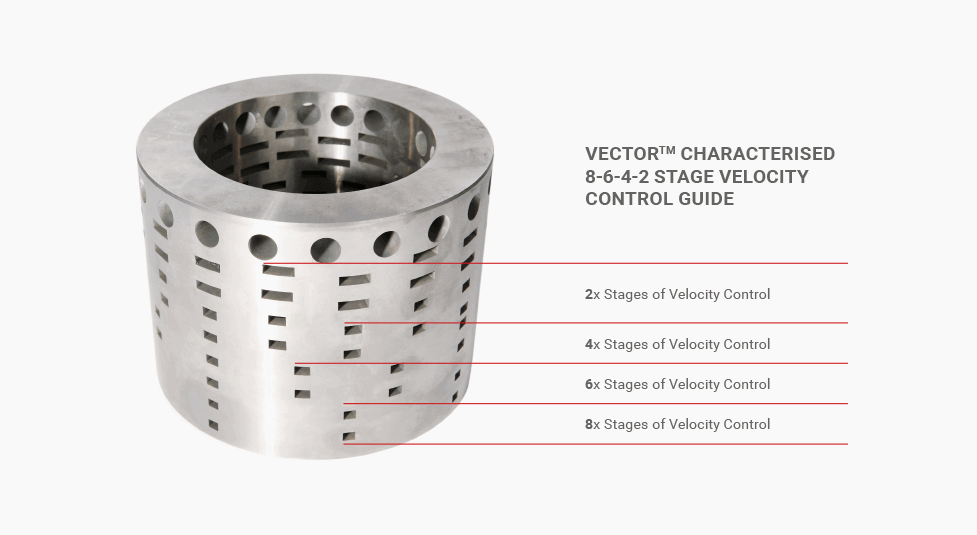

This VectorTM example shows how the well fluid is guided through a series of passages at each level on the trim. The well fluid then passes through a three-dimensional flow-path. The flow path areas expand after every turn which allows for the expansion of the gas phases, thus controlling the velocity at each 90 degree turn.

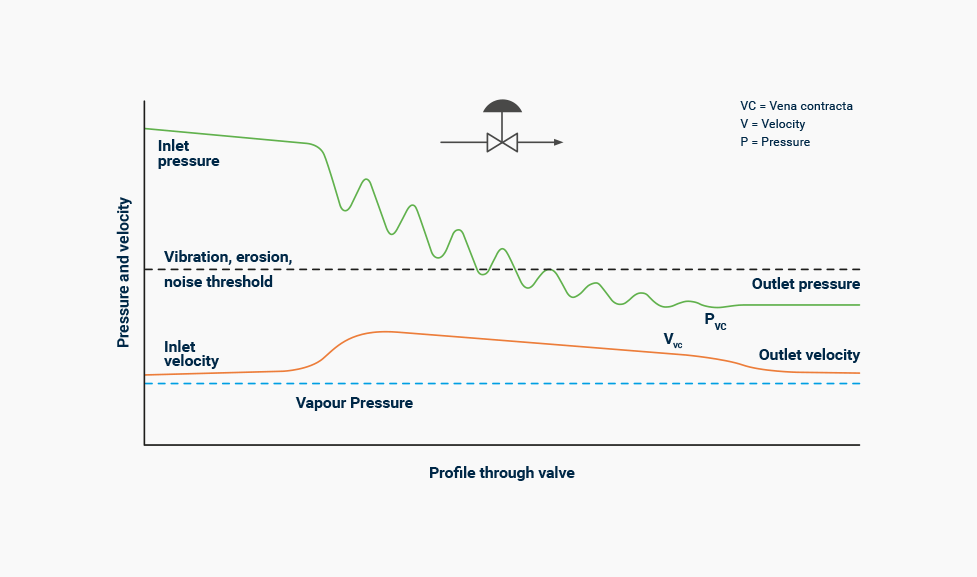

On liquid applications the Velocity Control principle ensures that the pressure profile through the choke does not go below the vapour pressure of the medium. This prevents the onset of harmful cavitation. The velocity is also controlled to ensure it does not go beyond the threshold for vibration, erosion and noise.

The VectorTM Vari-stage trim is used to meet the wide range of process parameters that a choke sees in its operational lifetime. It covers all conditions from initial high pressure drops and high velocities under low choke opening, to end of life conditions when well pressures have declined and high capacity flow is required.

Contact us to find out how our velocity control valve trims can help you maximise the efficiency and performance of assets in severe service conditions.

Subscribe to our newsletter to receive the latest updates from the Kent Introl team. If you enjoyed this article be sure to click the share buttons below!